Johan Berglund

Ph.D. Manufacturing Technology

Project time: 2016 – 2018

Budget: 9 750 000 kronor

Funding: SIP Produktion2030

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

AMtoFlex will strengthen the competitiveness of the Swedish manufacturing industry through improved production flexibility in the tooling manufacturing industries by novel design, manufacturing strategy, and assembly strategy through usage of emerging and novel technology like Additive Manufacturing (AM). In the tooling industry, the main challenge having a negative impact on the Swedish manufacturing industry is lead time, that on average is about 11 weeks, and for large and complex tools, as used in the automotive industry, can be as long as a year. Through utilization of AM, it is possible to address near-net-shape manufacturing incorporating internal cooling channels and removing time-consuming subsequent subtractive operations, and through digitalized approach work with a flexible supply chain. In addition, the AMtoFlex route will also be beneficial to tool performance; i.e. reducing the cycle times and improving

component quality. AMtoFlex contributes also to sustainable manufacturing through

significantly reducing the material waste, high material utilization in AMtoFlex route, beneficial for circular economy.

2014 – 2018

2015 – 2016

2017 – 2020

2014 – 2017

The goal is to demonstrate the additive manufacturing of micrometer/millimeter wave components.

2019 – 2022

2014 – 2017

2015 – 2016

Robotic solutions with autonomous decision-making software supporting on-demand production using resource pools.

2021 – 2024

2017 – 2021

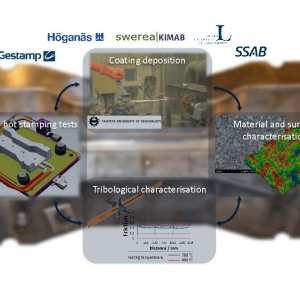

Tooling constitutes a significant part in the economical investment of the hot stamping process. Significant benefits in production economy and environmental benefits can be attained by improving the tribological performance in hot forming operations of automotive components. The main idea of this project is to create tailored tool surfaces on dies made from cheaper and easier to manufacture tool steel for the hot stamping of ultra-high strength steels.

2015 – 2018

IDAG aim to identify gaps and propose actions for the digital infrastructure necessary to industrialize additive manufacturing technologies. Actors from a new type of value chain of manufacturing companies – from powder to product – collaborate with digital solution providers and researchers to understand the needs and articulate the necessary actions through analysis of industrial cases. The target is to deliver a description in the form of a roadmap for how these actions can be developed and provided in order to ensure flexible and scalable digital platforms for additive manufacturing value chains.

2019 – 2019

2016 – 2019

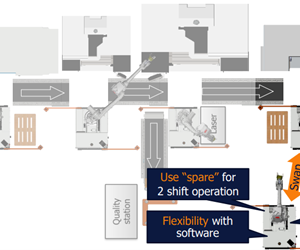

The project aims to develop a new cyber-physical framework to realize extremely flexible production.

2021 – 2024

2016 – 2018

2016 – 2018

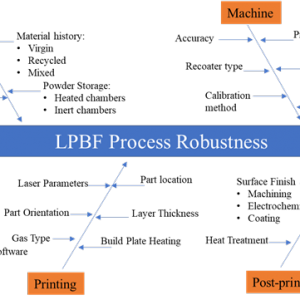

Assessing the Robustness of the Laser Powder Bed Fusion Process

2021 – 2024

2017 – 2018

The project's main goal is to develop a design and manufacturing methodology, for resource efficient additive manufacturing of components in the automotive industry.

2017 – 2020

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

2017 – 2018

2015 – 2016

2013 – 2017

2015 – 2016

Design process from concept to printable stl-file for AM including surface based networks in the structure.

2019 – 2022

2015 – 2016

2015 – 2016

2015 – 2016

2016 – 2017

2015 – 2018

2014 – 2016

2016 – 2017

2017 – 2019

2017 – 2018

2013 – 2016

2017 – 2020

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017

2017 – 2018

2016 – 2016

2013 – 2017

With globalization and other megatrends as demographic changes and climate change, more knowledge is needed regarding production in an international perspective. PADOK Study Visit in India 2016 have given an increased knowledge regarding how production is conducted in India, some of the challenges producing companies in that region is facing and how Swedish companies interested in investing in production in India could act to establish themselves in the region.

2016 – 2016

2016 – 2016

RemProLife aims at improving the use of life-cycle information to achieve more efficient remanufacturing from economic and ecological perpectives.

2013 – 2016

2016 – 2016

2016 – 2016

2017 – 2018

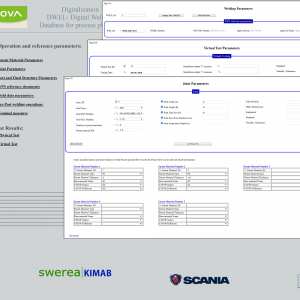

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

The overall goal of DiSAM is to create a unique test AM Hub in Sweden for metal and polymer based additive manufacturing processes.

2017 – 2021

2015 – 2015

2017 – 2018

2015 – 2016

2015 – 2017

The project aims to test the idea of an effective circulation system for material waste from additive manufacturing. Our goal is to map the prerequisites for closer collaboration between material suppliers and additive manufacturers, including new business models, partnerships and logistics solutions.

2017 – 2018

This project aims to contribute to the development of future ERP-systems. The project will explore how to offer work, redefine work roles and challenge companies to make use of advanced systems support and the technology within and around these. Overall, the project aims to contribute to the development of both the next generation of ERP-systems and a complementary change in the way firms see upon work organization, so that technology can support and meet the needs of the humans within organisations rather than enforcing structures upon them.

2019 – 2019

2014 – 2017

2013 – 2016

DIDAM develops and demonstrates digitalization solutions to industrialize Additive Manufacturing

2020 – 2023

2017 – 2018

2014 – 2017

2017 – 2018

2017 – 2018

The SAPPA project is about innovative cloud-based predictive and preventive maintenance systems, improving availability of products and production systems.

2014 – 2016

2015 – 2015

2014 – 2017

2014 – 2014

2015 – 2016

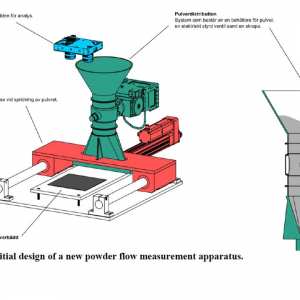

This project intends to design and develop a new test methodology for evaluation of power flowability in powder bed fusion (PBF) systems. The test apparatus will simulate powder flow in PBF machines and can be used for optimizing the powder layering behavior for potential utilization of alternative powder qualities. Additionally, this equipment creates opportunities for both powder producers and AM part manufacturers to minimize powder waste and maximize material utilization.

2017 – 2018

2015 – 2016

2015 – 2016

DiLAM strengthens the competitiveness of the Swedish manufacturing industry by aligning the digital and physical supply chains for additive manufacturing of large parts.

2017 – 2020

The aim of the project is to demonstrate utilization of additive manufacturing for copper-based products and process solutions and faster adaption

2016 – 2018

2014 – 2017

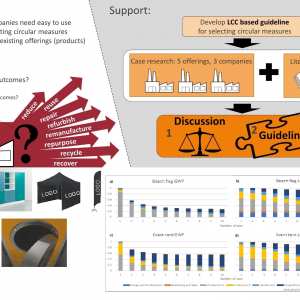

The project focuses on economic and environmental sustainability and increased industrial competitiveness.

2017 – 2018