Project time: 2017 – 2018

Budget: 714 000 kronor

Funding: SIP Produktion2030

This project intends to design and develop a new test methodology for evaluation of power flowability in powder bed fusion (PBF) systems. The test apparatus will simulate powder flow in PBF machines and can be used for optimizing the powder layering behavior for potential utilization of alternative powder qualities. Additionally, this equipment creates opportunities for both powder producers and AM part manufacturers to minimize powder waste and maximize material utilization.

Additive manufacturing (AM) of metallic components with powder bed fusion (PBF) technology is considered to be highly resource and material efficient. However, there are major shortcomings in the utilization of produced powders, largely due to the lack of characterization methods which are relevant to the function of metal-based machines.

Currently, a test apparatus which is capable of simulating the flow conditions in powder bed systems is not available. Consequently, the relation between powder characteristics and its flowability in PBF systems is not well understood. For this reason, existing PBF systems can only process powders within a narrow specification. As a result, powder manufacturers are restricted to utilize a small fraction of their overall production tonnage and, in spite of all the rigorous measures taken, it is not uncommon to find a batch of powder that has to be re-melted or disposed, simply because it does not fulfill the flowability requirements of current PBF machines.

Another source of material waste is re-circulated powder in PBF machines. Re-circulation alters powder flowability. Due to absence of a relevant testing principle the extent of change cannot be monitored. Hence, to avoid any potential risks, AM part producers tend to discard re-circulated powder prematurely.

The aim of this project is to design and develop a test apparatus for evaluation of powder layering performance. This tool can be used for optimizing the powder layer propagation behavior in powder bed AM, for potential utilization of alternative powder qualities. Additionally, this equipment creates opportunities for both powder producers and AM part manufacturers to minimize powder waste and maximize material utilization.

The project aims to test the idea of an effective circulation system for material waste from additive manufacturing. Our goal is to map the prerequisites for closer collaboration between material suppliers and additive manufacturers, including new business models, partnerships and logistics solutions.

2017 – 2018

IDAG aim to identify gaps and propose actions for the digital infrastructure necessary to industrialize additive manufacturing technologies. Actors from a new type of value chain of manufacturing companies – from powder to product – collaborate with digital solution providers and researchers to understand the needs and articulate the necessary actions through analysis of industrial cases. The target is to deliver a description in the form of a roadmap for how these actions can be developed and provided in order to ensure flexible and scalable digital platforms for additive manufacturing value chains.

2019 – 2019

Dynamic SALSA - Dynamic Scheduling of Assembly and Logistics Systems using AI

2023 – 2026

The overall goal of DiSAM is to create a unique test AM Hub in Sweden for metal and polymer based additive manufacturing processes.

2017 – 2021

DIDAM develops and demonstrates digitalization solutions to industrialize Additive Manufacturing

2020 – 2023

Hybrid joints, combination of gluing and mechanical joining are highly demanded where several materials are to be used and assembled. HJT therefore focuses on the smart factory's ability to create flexible production with simulation and programming in a digital twin that combines the latest technology for bonding, assembly and mechanical joining, rheology based simulation and automated collision-free planning. The projects goal is to focus on the whole hybrid joining process and to establish a testbed for hybrid joining as a resource for Swedish Industry.

2017 – 2020

DiLAM strengthens the competitiveness of the Swedish manufacturing industry by aligning the digital and physical supply chains for additive manufacturing of large parts.

2017 – 2020

The aim of the project is to demonstrate utilization of additive manufacturing for copper-based products and process solutions and faster adaption

2016 – 2018

The goal is to demonstrate the additive manufacturing of micrometer/millimeter wave components.

2019 – 2022

Design process from concept to printable stl-file for AM including surface based networks in the structure.

2019 – 2022

The project's main goal is to develop a design and manufacturing methodology, for resource efficient additive manufacturing of components in the automotive industry.

2017 – 2020

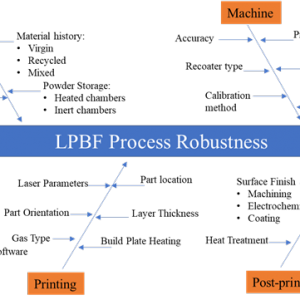

Assessing the Robustness of the Laser Powder Bed Fusion Process

2021 – 2024

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

Knowledge is needed that can support design and control of automation in material handling systems.

2019 – 2022