Project time: 2016 – 2018

Budget: 6 300 000 kronor

Funding: SIP Produktion2030

The aim of the project is to demonstrate utilization of additive manufacturing for copper-based products and process solutions and faster adaption

The aim of the project is to contribute to the utilization of emerging technologies such as additive manufacturing as enablers for innovative products and process solutions and faster adaption to market needs. The project addresses the area of Flexible Production, where combination of increased flexibility with novel product realization capability and shortened lead time will provide new competitive solutions when there is significant material cost involved. This will be demonstrated through the selected target applications regarding induction coils and copper-based parts.

The project addresses the powder-bed based AM-techniques selective laser melting and binder jetting. For each target application, the project covers the whole production chain from powder supply, powder tailoring and AM processing to design and end user or product owner assessment. The work includes the design for AM-fabricated Cu-parts, materials-driven process optimization and development of demonstrators and their assessment. Efforts will also include national and international results dissemination.

Design process from concept to printable stl-file for AM including surface based networks in the structure.

2019 – 2022

The project aims to test the idea of an effective circulation system for material waste from additive manufacturing. Our goal is to map the prerequisites for closer collaboration between material suppliers and additive manufacturers, including new business models, partnerships and logistics solutions.

2017 – 2018

Robotic solutions with autonomous decision-making software supporting on-demand production using resource pools.

2021 – 2024

IDAG aim to identify gaps and propose actions for the digital infrastructure necessary to industrialize additive manufacturing technologies. Actors from a new type of value chain of manufacturing companies – from powder to product – collaborate with digital solution providers and researchers to understand the needs and articulate the necessary actions through analysis of industrial cases. The target is to deliver a description in the form of a roadmap for how these actions can be developed and provided in order to ensure flexible and scalable digital platforms for additive manufacturing value chains.

2019 – 2019

The goal is to mirror the production and make custom information available for industry personnel.

2018 – 2019

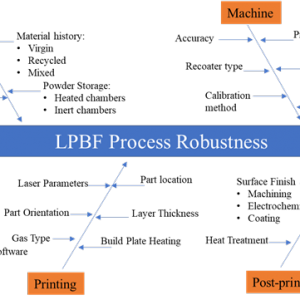

Assessing the Robustness of the Laser Powder Bed Fusion Process

2021 – 2024

DIDAM develops and demonstrates digitalization solutions to industrialize Additive Manufacturing

2020 – 2023

The project's main goal is to develop a design and manufacturing methodology, for resource efficient additive manufacturing of components in the automotive industry.

2017 – 2020

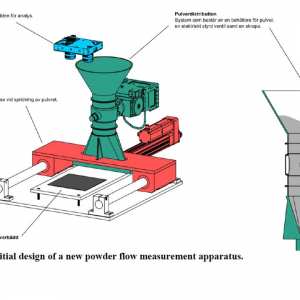

This project intends to design and develop a new test methodology for evaluation of power flowability in powder bed fusion (PBF) systems. The test apparatus will simulate powder flow in PBF machines and can be used for optimizing the powder layering behavior for potential utilization of alternative powder qualities. Additionally, this equipment creates opportunities for both powder producers and AM part manufacturers to minimize powder waste and maximize material utilization.

2017 – 2018

This project aims to contribute to the development of future ERP-systems. The project will explore how to offer work, redefine work roles and challenge companies to make use of advanced systems support and the technology within and around these. Overall, the project aims to contribute to the development of both the next generation of ERP-systems and a complementary change in the way firms see upon work organization, so that technology can support and meet the needs of the humans within organisations rather than enforcing structures upon them.

2019 – 2019

2013 – 2016

2014 – 2017

The overall goal of DiSAM is to create a unique test AM Hub in Sweden for metal and polymer based additive manufacturing processes.

2017 – 2021

DiLAM strengthens the competitiveness of the Swedish manufacturing industry by aligning the digital and physical supply chains for additive manufacturing of large parts.

2017 – 2020

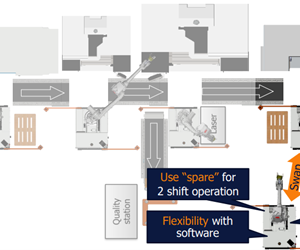

The project aims to develop a new cyber-physical framework to realize extremely flexible production.

2021 – 2024

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

The goal is to demonstrate the additive manufacturing of micrometer/millimeter wave components.

2019 – 2022

2014 – 2016

2016 – 2018