Interactive tool for increased knowledge content in the early stages of engineering design

2015 – 2016

Project time: 2014 – 2014

Budget: 500 000

Funding: SIP Produktion2030

The purpose of this Business Intelligence trips was to plan and carry out a study visit to the US and a number of sites of interest in manufacturing research, innovation and education.

A second purpose was also to increse and develop contacts to US-based reserachers´ and indsustry as well as establish connections betweeen the Swedish delegates.

Both of these goals were met.

The Swedish delegation got the opportunity to meet US-based reserachers and companies related to manufacturing research and innovation. Several people in the Swedish group has initiaded new collaboration´s with their US counterparts in reserch and education.

The delegates where chosen from steering committee and other parts of the organization around Produktion2030. The 18 people in the group represented industry, academia and research institutes. Six of them where Expert Group leaders in Produktion2030.

The programme manager together with Chalmers, AB Volvo and contacts in the US set up the agenda and made sure the right connections where made.

2015 – 2016

2015 – 2015

2015 – 2018

2015 – 2016

2016 – 2018

2014 – 2017

2016 – 2017

2016 – 2017

2015 – 2017

Tooling constitutes a significant part in the economical investment of the hot stamping process. Significant benefits in production economy and environmental benefits can be attained by improving the tribological performance in hot forming operations of automotive components. The main idea of this project is to create tailored tool surfaces on dies made from cheaper and easier to manufacture tool steel for the hot stamping of ultra-high strength steels.

2015 – 2018

2016 – 2016

2016 – 2016

2017 – 2020

2017 – 2018

2015 – 2016

2016 – 2019

2015 – 2016

With globalization and other megatrends as demographic changes and climate change, more knowledge is needed regarding production in an international perspective. PADOK Study Visit in India 2016 have given an increased knowledge regarding how production is conducted in India, some of the challenges producing companies in that region is facing and how Swedish companies interested in investing in production in India could act to establish themselves in the region.

2016 – 2016

2015 – 2016

2017 – 2018

2014 – 2017

2013 – 2016

2017 – 2018

2013 – 2016

2016 – 2016

2017 – 2021

The SAPPA project is about innovative cloud-based predictive and preventive maintenance systems, improving availability of products and production systems.

2014 – 2016

2015 – 2016

2017 – 2019

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

2015 – 2015

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017

2015 – 2016

2017 – 2018

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

2017 – 2018

2014 – 2016

2014 – 2017

RemProLife aims at improving the use of life-cycle information to achieve more efficient remanufacturing from economic and ecological perpectives.

2013 – 2016

2016 – 2016

2015 – 2016

2014 – 2017

2015 – 2016

2017 – 2020

2017 – 2018

2017 – 2018

2013 – 2017

2015 – 2016

2017 – 2018

2014 – 2017

2014 – 2018

2016 – 2018

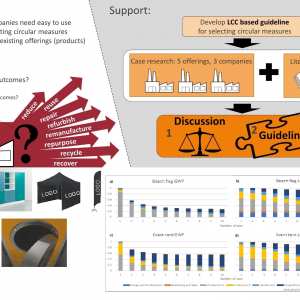

The project focuses on economic and environmental sustainability and increased industrial competitiveness.

2017 – 2018

2014 – 2017

2013 – 2017

2015 – 2016

2017 – 2018