A cyber-physical framework to support ultra-flexible production

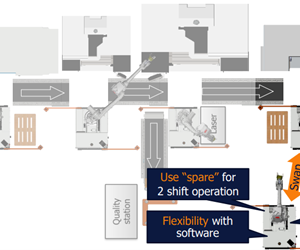

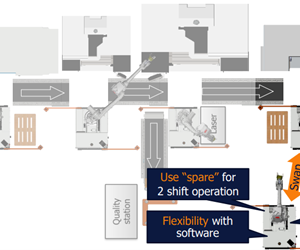

The project aims to develop a new cyber-physical framework to realize extremely flexible production.

2021 – 2024

The project aims to develop a new cyber-physical framework to realize extremely flexible production.

2021 – 2024

2016 – 2018

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

The aim of the project is to demonstrate utilization of additive manufacturing for copper-based products and process solutions and faster adaption

2016 – 2018

This project aims to contribute to the development of future ERP-systems. The project will explore how to offer work, redefine work roles and challenge companies to make use of advanced systems support and the technology within and around these. Overall, the project aims to contribute to the development of both the next generation of ERP-systems and a complementary change in the way firms see upon work organization, so that technology can support and meet the needs of the humans within organisations rather than enforcing structures upon them.

2019 – 2019

2013 – 2016

2014 – 2017

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

2014 – 2016

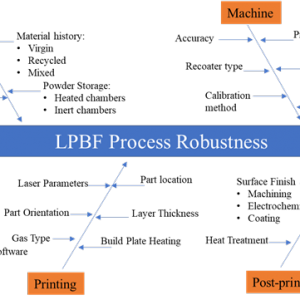

Assessing the Robustness of the Laser Powder Bed Fusion Process

2021 – 2024

Robotic solutions with autonomous decision-making software supporting on-demand production using resource pools.

2021 – 2024

We use cookies to improve the user experience and analyze user behavior. You can read more on the page About cookies.

Kunskapsförmedlingen

Kunskapsförmedlingen