Mikael Ström

Project time: 2015 – 2016

Budget: 657 000

Funding: SIP Produktion2030

Syftet med projektet var att testa digital teknik för interaktiva processer i tidiga skeden av en utvecklingsprocess. Målet för projektet var att besvara hypotesen ´om ett digitalt verktygs roll i utvecklingen av en tillverkares konkurrenskraft, och visa hur resultaten skall användas´. Hypotesen har testats på digitala verktyg för att konfigurera kablage hos AB Kontaktpressning och hypotesen anses vara delvis uppfylld.

Resultatet är: – Kunskap om kunder som köper kablage är insamlad – Processen att efterfråga, offerera, beställa, tillverka och leverera kablage är kartlagd – Kunskap om komponenter till kablage har samlats in – En enkel mockup har satts samman för att kommunicera kunskapen att välja kabel – En digital konfigurerare för produkter har testats Utfallet är att konfigureraren fungerar och kan hantera det konfigurationsproblem som vi ville lösa

Data har samlats in genom intervjuer med säljare, köpare och kabelexperter. Data har även samlats in genom att samla några av AB Kontaktpressnings kunder och processkartlägga fem olika anskaffningsprocesser och jämföra dessa. Kundernas utmaningar identifierades och analyserades med metoden fem varför. En digital konfigurerare har testats. För att kommunicera kunskap från AB Kontaktpressning till Swerea IVF har en enkle mockup satts samman som visar hur ett tänkt system bör utformas. Resultatet är sedan bedömt av AB Kontaktpressnings personal

2015 – 2016

2013 – 2016

2013 – 2017

RemProLife aims at improving the use of life-cycle information to achieve more efficient remanufacturing from economic and ecological perpectives.

2013 – 2016

2015 – 2016

The SAPPA project is about innovative cloud-based predictive and preventive maintenance systems, improving availability of products and production systems.

2014 – 2016

2017 – 2018

2017 – 2018

2014 – 2017

2014 – 2017

With globalization and other megatrends as demographic changes and climate change, more knowledge is needed regarding production in an international perspective. PADOK Study Visit in India 2016 have given an increased knowledge regarding how production is conducted in India, some of the challenges producing companies in that region is facing and how Swedish companies interested in investing in production in India could act to establish themselves in the region.

2016 – 2016

2015 – 2016

2016 – 2018

2013 – 2017

2017 – 2018

2017 – 2018

2015 – 2016

2016 – 2016

2014 – 2014

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

2014 – 2017

2015 – 2016

2016 – 2016

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

2017 – 2018

2015 – 2016

2016 – 2016

2017 – 2020

2017 – 2019

2015 – 2018

2015 – 2016

2017 – 2020

2015 – 2015

2017 – 2018

2014 – 2016

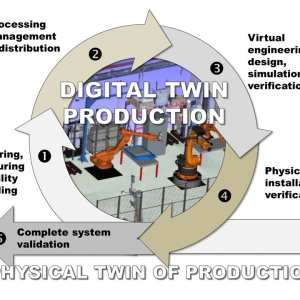

Methods for 3D scanned digital twins for efficient development and installation of production facilities at SMEs

2018 – 2021

2014 – 2017

2013 – 2016

2017 – 2018

2016 – 2017

2016 – 2016

2017 – 2018

2017 – 2021

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017

2014 – 2018

2015 – 2016

2015 – 2016

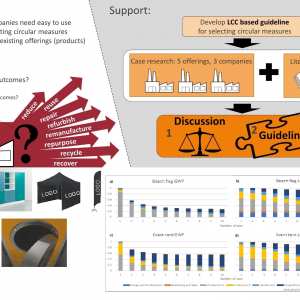

The project focuses on economic and environmental sustainability and increased industrial competitiveness.

2017 – 2018

2015 – 2016

2016 – 2017

2015 – 2015

2014 – 2017

2017 – 2018

2016 – 2019

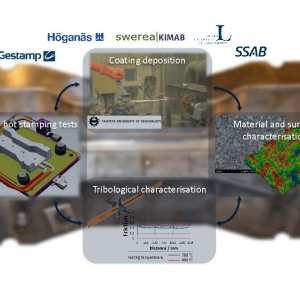

Tooling constitutes a significant part in the economical investment of the hot stamping process. Significant benefits in production economy and environmental benefits can be attained by improving the tribological performance in hot forming operations of automotive components. The main idea of this project is to create tailored tool surfaces on dies made from cheaper and easier to manufacture tool steel for the hot stamping of ultra-high strength steels.

2015 – 2018

2015 – 2017

2014 – 2017

2016 – 2018