Project time: 2015 – 2016

Budget: 775 000 kr

Funding: SIP Produktion2030

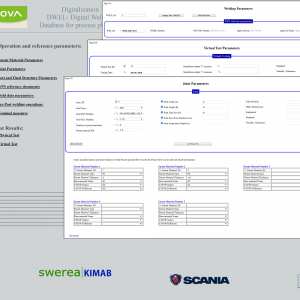

In the Digilean project w e have taken on the challenge to map digitalization needs in a manufacturing process, to facilitate know ledge creation and continuous learning based on disturbances and deviations. The overall objective of the project has been to develop a digitization concept for integrated improvement and know ledge flow in cooperation w ith Toyota Material Handling, Dentsply and Yolean. We have chosen to focus on problems identified in production, w ith its root causes pointing tow ards design.

The theory summarizes the Digilean process as: 1st step, procedures to identify deviations, 2nd step, Implementing procedures for solving problems, and 3rd step, to introduce a system for preventing the problem from reoccurring (i.e. organizational learning). We have in the project developed an information and process model based on the approach, and tested the applicability at Toyota and Dentsply. The information model and process model has been partially introduced and validated digitally in Dentsply (Step 1, in the production flow , and Step 2 evaluated on one production line)

The project has been carried out using a methodology based on a combination of experiments and qualitative studies in order to identify problems and test potential solutions iteratively. At Dentsply w e have used an existing system to log disturbances in production, delivered by Yolean, as the basis for experimentation. In the the Toyota case w e carried out a qualitative study in the production, idintifying and describing all stages of the Digilean Process. Toyota w as found to have a w ell-developed analog model, inherited from Japan, w ith great potential to be digitized.

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

With globalization and other megatrends as demographic changes and climate change, more knowledge is needed regarding production in an international perspective. PADOK Study Visit in India 2016 have given an increased knowledge regarding how production is conducted in India, some of the challenges producing companies in that region is facing and how Swedish companies interested in investing in production in India could act to establish themselves in the region.

2016 – 2016

2014 – 2017

2014 – 2017

2016 – 2018

2017 – 2019

Målet var att förstå de utmaningar som den svenska och japanska industrin står inför studiebesök.

2017 – 2018

2015 – 2016

2017 – 2018

2017 – 2018

2014 – 2017

2015 – 2015

2015 – 2016

2016 – 2016

2014 – 2018

2014 – 2017

2017 – 2021

RemProLife aims at improving the use of life-cycle information to achieve more efficient remanufacturing from economic and ecological perpectives.

2013 – 2016

2014 – 2014

2017 – 2018

2016 – 2016

2016 – 2018

2016 – 2017

The aim is to enable increased use of recycled material in polymer parts and to increase service life of products.

2022 – 2023

2015 – 2016

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017

2016 – 2016

2015 – 2018

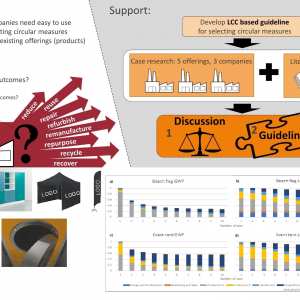

The project focuses on economic and environmental sustainability and increased industrial competitiveness.

2017 – 2018

2015 – 2017

2017 – 2018

2015 – 2016

2017 – 2018

2017 – 2018

2017 – 2020

2015 – 2016

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

2014 – 2017

2017 – 2020

2017 – 2018

2015 – 2016

2016 – 2017

2015 – 2016

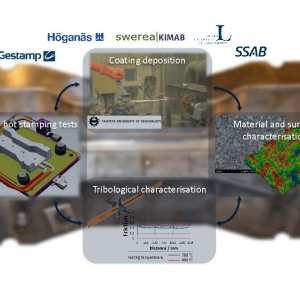

Tooling constitutes a significant part in the economical investment of the hot stamping process. Significant benefits in production economy and environmental benefits can be attained by improving the tribological performance in hot forming operations of automotive components. The main idea of this project is to create tailored tool surfaces on dies made from cheaper and easier to manufacture tool steel for the hot stamping of ultra-high strength steels.

2015 – 2018

2013 – 2016

2014 – 2017

2013 – 2017

2017 – 2018

2014 – 2016

2015 – 2016

2013 – 2017

2015 – 2016

2015 – 2016

2016 – 2019

2015 – 2015

2017 – 2018

2013 – 2016

The SAPPA project is about innovative cloud-based predictive and preventive maintenance systems, improving availability of products and production systems.

2014 – 2016

2016 – 2016