Project time: 2018 – 2021

Budget: 10 630 000 kronor

Methods for 3D scanned digital twins for efficient development and installation of production facilities at SMEs

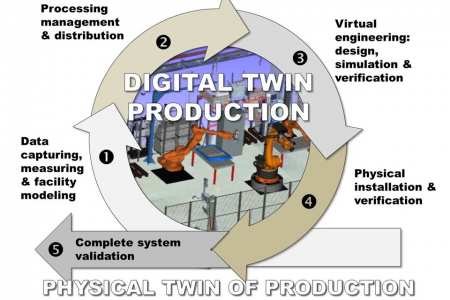

There is a pronounced need to reduce cost, time and difficulties for automation system and line builders to properly model, design and install equipment. With technology and working methods for 3D scanning of production facilities, a digital twin of the production system can easily be created. This can be used to support layout planning, 3D geometry, programming, installation, and calibration. The project’s goal is to develop customized and useful methods for small and medium-sized businesses based on established state-of-the-art business practices.

The project develops a methodology for SMEs to create digital twins of their production environment and a web-based environment for trouble-free storage and access. In addition, a methodology is proposed for layout planning, 3D design, and robotic programming in the digital twin. Essential result is the methodology for installation and adjustment so that the physical installation turn out exactly as the modeled digital twin. The project provides SMEs the benefits of 3D scanning. Thus allowing equipment to be installed faster, with increased quality, fewer errors and reduced costs.

The project is carried out by partners with knowledge of 3D scanning (RISE, Chalmers, ATS, GIAB, Volvo Cars, Volvo Trucks) together with manufacturing companies (Parker Hannifin, Plastal, KB Components and Blomdahls), automation vendors (Plamex and 3ButtonGroup) and software vendors / consultants (Siemens Industrial Software and Summ Systems). Case studies will be conducted in the project at participating companies. The work is divided into work packages for current state, digitization / web environment, modelling, installation / adjustment, Dissemination, and management.

Vinnova Dnr: 2018-02698

A research collaboration between Luleå University of Technology and the company RGS 90 will provide new treatment methods for three common but problematic types of waste.

2015 – 2019

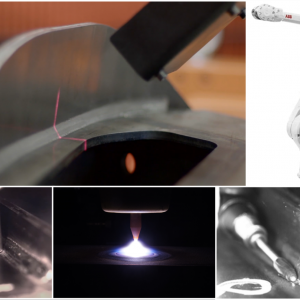

To demonstrate the new technology with robots that enable Swedish companies to develop innovative new products for automated production o maintenance.

2017 – 2020

The project aims at radically improving the working environment and the employee security within the heavy manufacturing industries by using and adapting the latest technology for low and ultraprecise positioning and decision support systems. The target is to increase security and safety by adapting the decision-support and positioning system for the heavy manufacturing industries.

2017 – 2018

The aim of the ARR project is to develop the potential of automation in repairs and remanufacturing

2018 – 2021

The project's goal is to assist industry enabling sustainable work for operators during assembly of wire harnesses.

2022 – 2025

2013 – 2017

Digi-load focuses on to enhance the competitiveness in the Swedish surface treatment industry through automation and digitalization

2017 – 2020

TriBlade is a new ground-breaking technology for rotor blades in wind turbines, which have the potential to affect the entire wind power market. The technology has been developed by Winfoor in collaboration with Lund University and is based on each rotor blade designed as a truss.

2015 – 2019

2015 – 2016

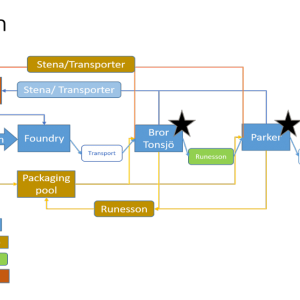

SCARCE II will develop a demonstrator to show how SMEs and associated value flows can increase efficiency, competitiveness, sustainability and internal collaboration through digitalisation. The goal is to show the value of a new digital solution. SCARCE focuses on two subcontractors in the value chain linked to Scania and Volvo. The demonstrator is a cloud-based solution that connects three test beds in the industry; Stena Industry Innovation Lab, Chalmers, RISE IVF lab, Mölndal and KTH's test bed in Södertälje with the help of Siemens, AFRY, Qbim, Virtual Manufacturing and EQPack.

2020 – 2022

MIDWEST will develop mechanisation solutions for Post-weld treatment methods of welded components.

2020 – 2023

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

Knowledge is needed that can support design and control of automation in material handling systems.

2019 – 2022

2015 – 2016

The SQID project will develop an industrial cleaning and drying machine using Qlean water instead of traditional chemicals.

2016 – 2018

Maintenance in existing plants is becoming increasingly important, where predictive maintenance has become an emerging technology. The use of decision support tools contributes to environmentally and economically sustainable production. Within this project, different types of digital twins have been designed and evaluated. Specifically, new predictive model types have been tested in two different industrial case studies; a heat exchanger at SSAB and a profiled header at Svenska Fönster AB.

2017 – 2018

The project created a sustainable test bed that by provides Swedish industry with facilities and tools to physically and virtually evaluate different manufacturing concepts.

2013 – 2016