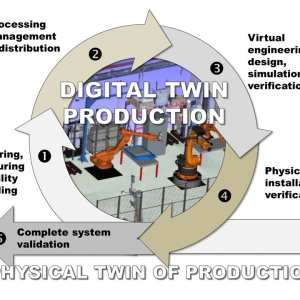

SCARCE II will develop a demonstrator to show how SMEs and associated value flows can increase efficiency, competitiveness, sustainability and internal collaboration through digitalisation. The goal is to show the value of a new digital solution. SCARCE focuses on two subcontractors in the value chain linked to Scania and Volvo. The demonstrator is a cloud-based solution that connects three test beds in the industry; Stena Industry Innovation Lab, Chalmers, RISE IVF lab, Mölndal and KTH's test bed in Södertälje with the help of Siemens, AFRY, Qbim, Virtual Manufacturing and EQPack.

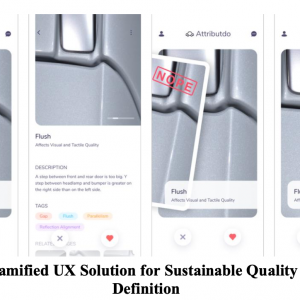

Today’s digital solutions for IoT platforms, automation solutions and transparent systems for displaying real-time data enable better planning and control in the value chain for SMEs. Nevertheless, it is possible to get digital solutions that can buy and if they are to be the main one for monitoring the production processor, where the potential of digitization that is not exploited. SCARCE II focuses on two subcontractors located in the value chain linked to Scania and Volvo. SCARCE I identified the following challenges: i) categorizing disruptions in production to provide what data is needed to better plan productions ii) adapting digital flows to introduce automation in material handling and iii) tracking packaging to increase efficiency and left linked to sustainability and ergonomics. In SCARCE II, a demonstrator will meet the challenges and show SMEs and their associated value streams that it is possible to increase efficiency, competitiveness and international collaboration through digitalization. The demonstrator will be a cloud-based solution that connects three test beds via pilots in the industry; Stena Industry Innovation lab, at Chalmers, RISE IVF lab in Mölndal and KTH’s testbed Södertälje are linked with the help of technology suppliers Siemens, ÅF, Qbim and Virtual Manufacturing. The pilots that are being developed at the subcontractors are P1 Digitized information in planning and material handling and P2 Emballage management. Linked to the project is a focus group with members from a haulage company and partners from the value chain such as Scania and Stena Metall, as well as participation from the Digitala Stambanan which will provide input to the development and results of digital solutions.

Kunskapsförmedlingen

Kunskapsförmedlingen