Farazee Asif

Project time: 2019 – 2019

Budget: 499 300 kronor

Funding: SIP Produktion2030

The project objective is to lay a foundation to develop a digital platform that can enable generating materials passports for products to facilitate implementation of Circular Production Systems.

Transition towards circular economy (CE) through implementing Circular Production Systems (CPS) has become inevitable to mitigate challenges of resource scarcity and resource price volatility as well as ensure sustainable development. Furthermore, there is a huge economic potential for the industry to be tapped through high quality value recovery in the form of products or materials by implementing CPS. However, one of the challenges with implementation of CPS is to ensure integration and flow of information across the value chains so that right value recovery activities can be performed efficiently to recover value. Traditionally, information management systems in industry are not designed for value recovery and there is always a risk for breach in information sharing across the value chains and trade-levels. Although the manufacturing industry is known to be highly efficient in product data management, the data management systems have seldom been designed to facilitate the circular flow of products or materials. Therefore, the project aims to lay a foundation to develop a digital platform that can enable generating material passports to facilitate implementation of CPS. The platform will establish connection between different value chain actors and enable them to share product and material information throughout multiple lifecycle of products. Such a platform can also provide support for product compliance, increase transparency across value chains, sustainable sourcing and efficient recovery of materials etc.

The project will assess the applicability of the concept of ‘material passport’ in the manufacturing industry by involving a cross functional group represented by researchers, manufacturers, software developers and recycling experts.

To create an inventory of AI techniques for maintenance services, apply AI techniques to three industrial cases, and evaluate their economic and environmental implications.

2017 – 2019

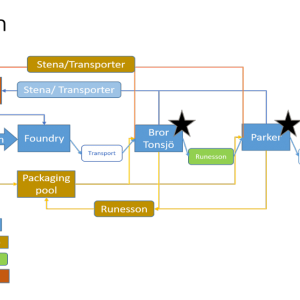

SCARCE will investigate the needs, possibilities and obstacles in value chains up- and down-stream from a focal SME company. SCARCE will explore what data to measure and visualize, and how this data can enable more automated execution, as well as, more dynamic and proactive planning of production capacity and material flows across the companies in the value chain. In addition, we will study organizational capabilities, especially the future human role, for implementing and managing in a digital and data-driven value chain.

2019 – 2019

SE:Kond2Life - Ecosystem for reuse of automotive components

2019 – 2022

Roundtables with governmental organizations and industry regarding circular economy and product related legislation

2020 – 2021

Developing circular production systems using digital technologies

2021 – 2024

To lay the foundation for tomorrow’s network of circular economy microfactories producing products designed by Swedish industry and produced from local recycled plastics.

2022 – 2023

SCARCE II will develop a demonstrator to show how SMEs and associated value flows can increase efficiency, competitiveness, sustainability and internal collaboration through digitalisation. The goal is to show the value of a new digital solution. SCARCE focuses on two subcontractors in the value chain linked to Scania and Volvo. The demonstrator is a cloud-based solution that connects three test beds in the industry; Stena Industry Innovation Lab, Chalmers, RISE IVF lab, Mölndal and KTH's test bed in Södertälje with the help of Siemens, AFRY, Qbim, Virtual Manufacturing and EQPack.

2020 – 2022

Measure environmental performance and improve towards eco-efficient, climate-friendly and circular production

2022 – 2023