Project time: 2017 – 2018

Budget: 4 900 000 kronor

Funding: SIP Produktion2030

The project aims at radically improving the working environment and the employee security within the heavy manufacturing industries by using and adapting the latest technology for low and ultraprecise positioning and decision support systems. The target is to increase security and safety by adapting the decision-support and positioning system for the heavy manufacturing industries.

The project aims at radically improving the working environment and the employee security within the heavy manufacturing industries by using and adapting the latest technology for low and ultraprecise positioning and decision support systems. Within the heavy industries there are annually severe incidents, injuries and even death causalities due to miscommunication between humans and human/machines. By further adapting existing and utilizing the latest technology within the area of communication and positioning we can use state-of-the-art technology to minimize the risks of incidents and simultaneously, increase the efficiency and improve the logistics of humans and equipment within the heavy manufacturing industries. In many ways, this development towards controlled work environment is a vital step toward the digital factory as more automated equipment will increase the demand on surveillance, security and control within the large industrial complex out of personal security and work environment. This technology will be a paradigm shift within the heavy industry from a safety, security and work environment point of view. Most people who have visited heavy manufacturing industries can relate to how own employers, suppliers and sub-suppliers move within the area. The combination of humans, heavy equipment, vehicles, high temperatures, electricity, chemicals, magnetic fields etc. makes up for an area of great risks for the own work force and, especially, suppliers. The magnetic fields, the vast open and under roof areas, basements, culverts and dust etc. make radio communication difficult and sometimes not even possible and this gives rise to several implications from a safety point of view.

The development of this technology will enable secure and flexible production and improved humans and human/machine interaction under severe conditions, and addresses Production 2030 strength area 4. This project will lead to increased productivity, efficiency and keeping Swedish industry in the forefront of communication, digitalization and automatization by utilizing existing large scale testbed and the latest available positioning technology. By using the existing testbed at Swerea MEFOS, and complementing the pre-industrial environment with top-notch position technology, the project will enable further development and adaptations for the specific industry need, whether it may be automatization, production methods and logistics, disruptive sources or specific geo-fencing. The need for a pre-industrial testbed utilizing and accessing this kind of technology tests is large as we move further towards the factories of the future.

Reduce the environmental impact of foundries by reducing the amount of sand waste using machine learning.

2023 – 2024

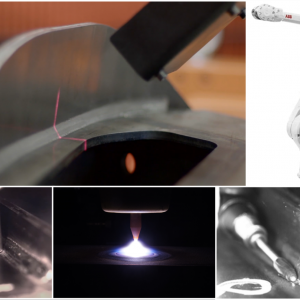

The project aims a digitising the temperatures during the casting of rolls and suggest actions to the casting manager to reduce the variability of the process

2015 – 2016

Developing circular production systems using digital technologies

2021 – 2024

Tidsättning av manuell montering är centralt för verkstadsindustrins konkurrenskraft.

2021 – 2024

The project aims to use deviation data for improving the product design and production.

2020 – 2023

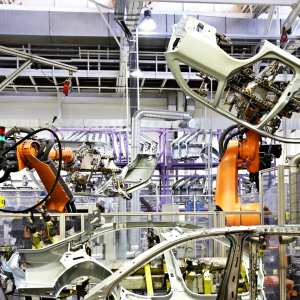

To demonstrate the new technology with robots that enable Swedish companies to develop innovative new products for automated production o maintenance.

2017 – 2020

DiLAM strengthens the competitiveness of the Swedish manufacturing industry by aligning the digital and physical supply chains for additive manufacturing of large parts.

2017 – 2020

Circular handheld machines; from an environmental and human perspective (Zero Vibration Circularity)

2024 – 2027

WELDVISI will create a new sensor-based assistance system for manual manufacturing with real-time cognitive feedback and documentation of parameters.

2022 – 2025

The project aims at facilitating the implementation of Smart Maintenance through extended collaboration within the maintenance community.

2017 – 2019

DiVISI aims at investigating how sharing of digital information can improve the forest-forest industry value chain.

2020 – 2023

MIDWEST will develop mechanisation solutions for Post-weld treatment methods of welded components.

2020 – 2023

The project's goal is to assist industry enabling sustainable work for operators during assembly of wire harnesses.

2022 – 2025

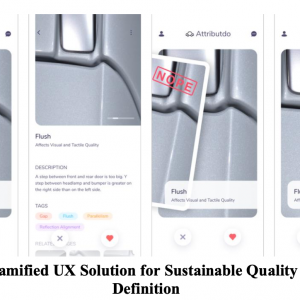

Two major disruptive trends – electrification and digitalization are changing customer preferences, leading to the probably most substantial transformation in the automotive industry we observed in decades. Finding a balance between customer’s requirements towards “zero-emission vehicle,” “connected car,” choice of materials, clarity of functions, and interface modes under the pressure of production time and cost are not easy. The AttributDo-project aims to help engineers create, define, verify and validate new and existing design features for new product development.

2021 – 2021

Digi-load focuses on to enhance the competitiveness in the Swedish surface treatment industry through automation and digitalization

2017 – 2020

The paintshop is often a bottleneck in production and the processes are fine-tuned based on testing on numerous prototypes. To meet the future demands there is a great need to improve the product preparation process. The aim is to develop methods, techniques and software, and supporting measurement methodology, for simulation of paint curing in IR and convective ovens. The goal is to assist the industry to further develop and optimize their surface treatment to be more energy and cost efficient; to have a shorter lead time in product development; and to give a higher product quality.

2016 – 2019

The project aims to digitalize established tools for production disturbance handling.

2018 – 2020

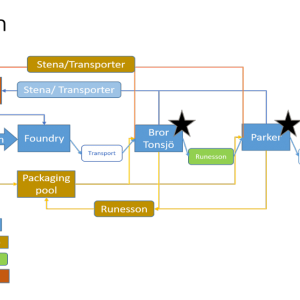

SCARCE II will develop a demonstrator to show how SMEs and associated value flows can increase efficiency, competitiveness, sustainability and internal collaboration through digitalisation. The goal is to show the value of a new digital solution. SCARCE focuses on two subcontractors in the value chain linked to Scania and Volvo. The demonstrator is a cloud-based solution that connects three test beds in the industry; Stena Industry Innovation Lab, Chalmers, RISE IVF lab, Mölndal and KTH's test bed in Södertälje with the help of Siemens, AFRY, Qbim, Virtual Manufacturing and EQPack.

2020 – 2022

This project aims to contribute to the development of future ERP-systems. The project will explore how to offer work, redefine work roles and challenge companies to make use of advanced systems support and the technology within and around these. Overall, the project aims to contribute to the development of both the next generation of ERP-systems and a complementary change in the way firms see upon work organization, so that technology can support and meet the needs of the humans within organisations rather than enforcing structures upon them.

2019 – 2019

The aim of the ARR project is to develop the potential of automation in repairs and remanufacturing

2018 – 2021

The project will develop a concept for production workers to easily build simple low-cost IoT-aided improvement solutions at the production shop floor.

2018 – 2020

Målet var att förstå de utmaningar som den svenska och japanska industrin står inför studiebesök.

2017 – 2018

Improve the efficiency of sawmills, including improved monitoring and maintenance of the production line. This by sharing data via digital twin between the actors in the maintenance chain.

2019 – 2019

Novel methods, techniques and software for simulation of electrodeposition and galvanization processes.

2020 – 2023

SCARCE will investigate the needs, possibilities and obstacles in value chains up- and down-stream from a focal SME company. SCARCE will explore what data to measure and visualize, and how this data can enable more automated execution, as well as, more dynamic and proactive planning of production capacity and material flows across the companies in the value chain. In addition, we will study organizational capabilities, especially the future human role, for implementing and managing in a digital and data-driven value chain.

2019 – 2019

The project aims to reduce the lead time for sheet metal die tryout by optimizing the value stream and develop methods for numerical compensation of die and press deflections.

2017 – 2019

Method to understand how to automate information handling to get more efficient handling of production deviations.

2018 – 2020

A research collaboration between Luleå University of Technology and the company RGS 90 will provide new treatment methods for three common but problematic types of waste.

2015 – 2019

Knowledge is needed that can support design and control of automation in material handling systems.

2019 – 2022

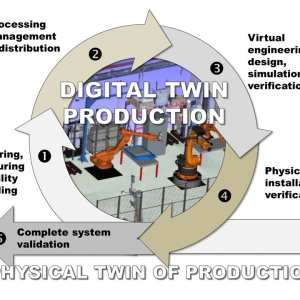

Methods for 3D scanned digital twins for efficient development and installation of production facilities at SMEs

2018 – 2021

Maintenance in existing plants is becoming increasingly important, where predictive maintenance has become an emerging technology. The use of decision support tools contributes to environmentally and economically sustainable production. Within this project, different types of digital twins have been designed and evaluated. Specifically, new predictive model types have been tested in two different industrial case studies; a heat exchanger at SSAB and a profiled header at Svenska Fönster AB.

2017 – 2018

Demonstrations of a digital infrastructure that supports manufacturing by creating a digital twin of the production system based on existing IT applications for development.

2017 – 2020

The overall goal of DiSAM is to create a unique test AM Hub in Sweden for metal and polymer based additive manufacturing processes.

2017 – 2021

DIDAM develops and demonstrates digitalization solutions to industrialize Additive Manufacturing

2020 – 2023