Project time: 2017 – 2018

Budget: 720 876 kronor

Funding: SIP Produktion2030

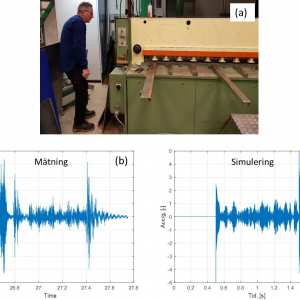

Maintenance in existing plants is becoming increasingly important, where predictive maintenance has become an emerging technology. The use of decision support tools contributes to environmentally and economically sustainable production. Within this project, different types of digital twins have been designed and evaluated. Specifically, new predictive model types have been tested in two different industrial case studies; a heat exchanger at SSAB and a profiled header at Svenska Fönster AB.

Measured data from the plants have been acquired from existing control systems and with a complementary measurement system. The modeling work has been done offline and analysis of the results has been done jointly by model developers and staff with process knowledge. The aim has been to find general methods for smart maintenance in existing industrial plants. The methods have been evaluated for both usability in specific applications and how well they can be generalized for any industrial plant. The model showing best overall results is method based on latent variables (Lava). A quality of the LAVA model is that the calculated model has few nonlinear terms and thus the problems of over-parametrization that may occur when flexible model types are used in model estimation can be reduced. The LAVA model is a Black box model. The advantage of black box models is that they are general; however, process knowledge is still necessary for successful implementations. The results from the project are promising, but a longer test period is required to rule out e.g. seasonal variations. In addition, a technical platform has been identified for implementation in existing plants.

Industrial production systems typically include many process steps performed by automatic or semi-automatic machines. Depending on the different variables, these machines age and thereby affecting both the quality of the manufacturing step and the resource requirements

2017 – 2018

Improve the efficiency of sawmills, including improved monitoring and maintenance of the production line. This by sharing data via digital twin between the actors in the maintenance chain.

2019 – 2019

Recent research from Chalmers have shown that by slightly tuning robot motions, the energy use can be reduced by 10 –30%, with preserved cycle time.

2017 – 2020

The objective is to bring together expertise from AI and LCE to Product/Service Systems for Swedish manufacturing firms in a multidisciplinary research effort to utilise latest techniques efficiently for Swedish production industry. The goal is to make a plan of developing demonstrators in production and maintenance using artificial intelligence techniques, digital technologies and lifecycle engineering methods

2019 – 2019

A research collaboration between Luleå University of Technology and the company RGS 90 will provide new treatment methods for three common but problematic types of waste.

2015 – 2019

Knowledge is needed that can support design and control of automation in material handling systems.

2019 – 2022

The aim of the ARR project is to develop the potential of automation in repairs and remanufacturing

2018 – 2021

To create an inventory of AI techniques for maintenance services, apply AI techniques to three industrial cases, and evaluate their economic and environmental implications.

2017 – 2019

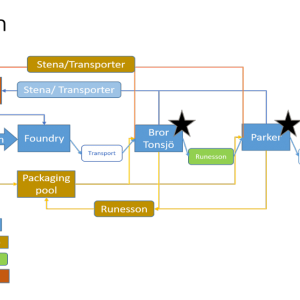

SCARCE II will develop a demonstrator to show how SMEs and associated value flows can increase efficiency, competitiveness, sustainability and internal collaboration through digitalisation. The goal is to show the value of a new digital solution. SCARCE focuses on two subcontractors in the value chain linked to Scania and Volvo. The demonstrator is a cloud-based solution that connects three test beds in the industry; Stena Industry Innovation Lab, Chalmers, RISE IVF lab, Mölndal and KTH's test bed in Södertälje with the help of Siemens, AFRY, Qbim, Virtual Manufacturing and EQPack.

2020 – 2022

The project's goal is to assist industry enabling sustainable work for operators during assembly of wire harnesses.

2022 – 2025

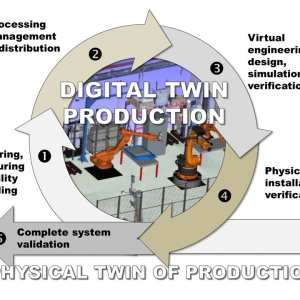

Demonstrations of a digital infrastructure that supports manufacturing by creating a digital twin of the production system based on existing IT applications for development.

2017 – 2020

The project aims to digitalize established tools for production disturbance handling.

2018 – 2020

The project aims at radically improving the working environment and the employee security within the heavy manufacturing industries by using and adapting the latest technology for low and ultraprecise positioning and decision support systems. The target is to increase security and safety by adapting the decision-support and positioning system for the heavy manufacturing industries.

2017 – 2018

Methods for 3D scanned digital twins for efficient development and installation of production facilities at SMEs

2018 – 2021

Realizing the future of maintenance in battery production for a sustainable and competitive battery industry.

2023 – 2026

Digi-load focuses on to enhance the competitiveness in the Swedish surface treatment industry through automation and digitalization

2017 – 2020

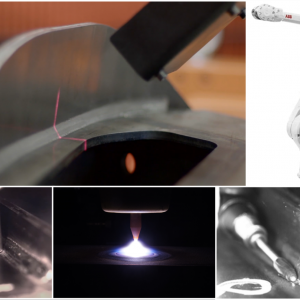

MIDWEST will develop mechanisation solutions for Post-weld treatment methods of welded components.

2020 – 2023

The project aims at facilitating the implementation of Smart Maintenance through extended collaboration within the maintenance community.

2017 – 2019

To demonstrate the new technology with robots that enable Swedish companies to develop innovative new products for automated production o maintenance.

2017 – 2020

En hållbar batterisektor i Sverige genom effektivt underhåll av framtidens batteriproduktion.

2022 – 2023