Project time: 2017 – 2018

Budget: 499 500 kronor

Funding: SIP Produktion2030

Industrial production systems typically include many process steps performed by automatic or semi-automatic machines. Depending on the different variables, these machines age and thereby affecting both the quality of the manufacturing step and the resource requirements

Industrial production systems typically include many process steps performed by automatic or semi-automatic machines. Depending on the different variables, these machines age and thereby affecting both the quality of the manufacturing step and the resource requirements. Existing state-of-the-art monitoring systems typically do not conform to either the historical outcome or predicted future outcomes, which means that many industrial stages of production today are conducted in an unsustainable manner w ith quality problems, waste, disposals, overconsumption of resources, etc. as a result. To address these problems, the idea to be tested in this project is that the unique response signature of the manufacturing machine, together with information about the environment and production output can be used to generate an adaptive digital twin. The idea is to use the adaptive digital twin to predict optimal production output and then control the machine as well as to plan service and maintenance fulfilling this prediction. This digitized prediction-based production optimization system will be tested by two research groups at Luleå Technical University and personnel at SSAB Borlänge through a case study. There is a great value of this idea which can contribute to significantly increased sustainability in industrial production

TriBlade is a new ground-breaking technology for rotor blades in wind turbines, which have the potential to affect the entire wind power market. The technology has been developed by Winfoor in collaboration with Lund University and is based on each rotor blade designed as a truss.

2015 – 2019

The objective is to bring together expertise from AI and LCE to Product/Service Systems for Swedish manufacturing firms in a multidisciplinary research effort to utilise latest techniques efficiently for Swedish production industry. The goal is to make a plan of developing demonstrators in production and maintenance using artificial intelligence techniques, digital technologies and lifecycle engineering methods

2019 – 2019

The EVASTIR project will support the Swedish automotive industry with the transition from internal combustion engine to battery electric vehicles, while introducing new sustainable manufacturing processes. This project will develop a welding process, FSW, to support design and fabrication a cost-effective, scalable, lightweight and crash-resistant battery tray for electric vehicles. The specific technical objectives of this project are to develop FSW procedures for dissimilar material joints of cast and extruded aluminium alloys and for high speed welding to 5m/min.

2019 – 2021

The goal of AutoFix is to increase automation of fixture design with integration of digital tools from different disciplines.

2020 – 2023

Maintenance in existing plants is becoming increasingly important, where predictive maintenance has become an emerging technology. The use of decision support tools contributes to environmentally and economically sustainable production. Within this project, different types of digital twins have been designed and evaluated. Specifically, new predictive model types have been tested in two different industrial case studies; a heat exchanger at SSAB and a profiled header at Svenska Fönster AB.

2017 – 2018

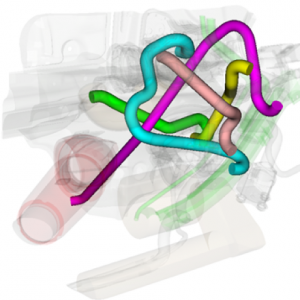

AutoPack skapar optimala elkablageinstallationer baserat på optimering och maskininlärning. AutoPack delivers optimal cabling installations based on optimization and machine learning

2021 – 2023

Demonstrations of a digital infrastructure that supports manufacturing by creating a digital twin of the production system based on existing IT applications for development.

2017 – 2020

The goal is to mirror the production and make custom information available for industry personnel.

2018 – 2019

The long-term goal of the research project is to develop hardware and software platform, i.e. modular systems that enables production workers to easily build and implement IoT-aided improvement solutions at the production shop floor

2017 – 2018