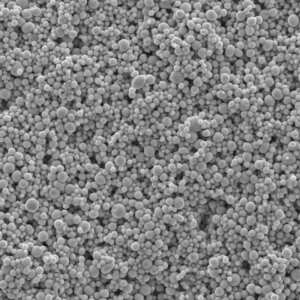

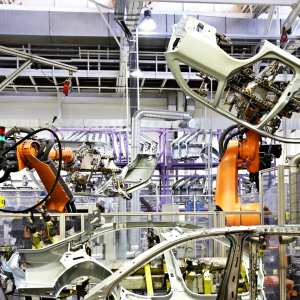

Reduce the environmental impact of foundries by reducing the amount of sand waste using machine learning.

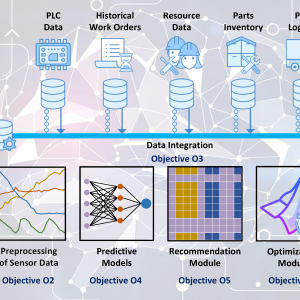

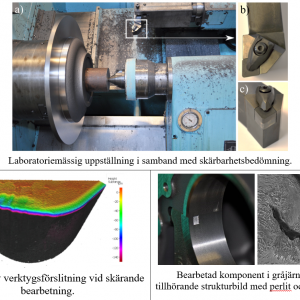

This project stands as a pioneering endeavour to digitally transform the casting process in foundries, by integrating empirical measurements, numerical modelling, and machine learning within sand reclamation processes.

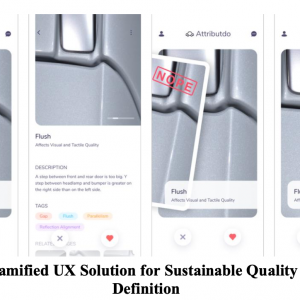

Currently, there is lack of scientific understanding and expertise amongst foundries to discern how different recycling routes and sand molding process parameters impact the casting quality. The project aims to introduce a machine learning sand reclamation model to assist foundries in optimizing process parameters, better manage their sand recycling process, optimize their material consumption, and decrease the amount of cast defects.

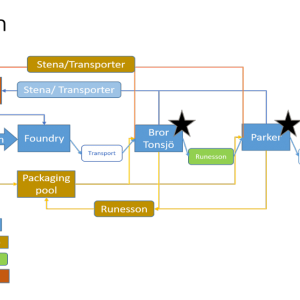

Through the cooperation between the partners within this project results from basic research and applied research can be quickly implemented to the sand system of the industry.

Kunskapsförmedlingen

Kunskapsförmedlingen