Project time: 2020 – 2023

Budget: 8 490 682 kr

The goal of AutoFix is to increase automation of fixture design with integration of digital tools from different disciplines.

In Autofix we want to introduce automation based on multidisciplinary optimization (MDO) and machine learning (ML). AutoFix delivers methods and tools that automatically optimize resource-intensive fixture design using design automation (DA), MDO, and ML.

We want to enable the possibility of in-sourcing from low-wage countries by allowing more work to be carried out while maintaining engineering hours. Efficient knowledge management and standardization that facilitates engineering work, which frees up time that can be used for value-creating activities and thereby increase efficiency in product and production development and thereby strengthen companies competitiveness. Knowledge building in the area of digitization in general, and specifically how machine learning creates better decision support in product and production development.

The project consists of five main work packages (WPs), summarized below: WP1 To develop new methods for creating detailed CAD models and for configuring them. WP2: Exploring the design space in a new way and optimizing fixtures WP3. To generate patterns and CAD instructions automatically using ML algorithms based on data generated from the MDO process in WP2. WP4 The methods developed in WP1 to WP4 are evaluated against the current development process WP5 The results of the project are spread continuously to create a broad utilization

Prediktivt underhåll med internet-of-things och digitala tvillingar

2021 – 2021

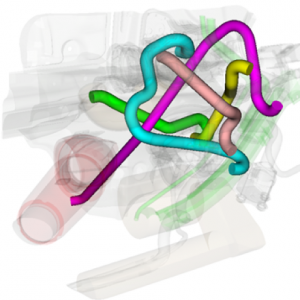

AutoPack skapar optimala elkablageinstallationer baserat på optimering och maskininlärning. AutoPack delivers optimal cabling installations based on optimization and machine learning

2021 – 2023

Reduce the environmental impact of foundries by reducing the amount of sand waste using machine learning.

2023 – 2024

The aim is to develop new models for visualizing and predicting delivery schedule variations in supply chains.

2018 – 2021

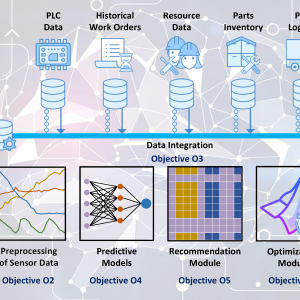

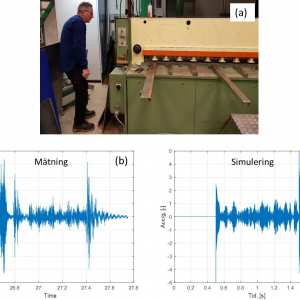

Industrial production systems typically include many process steps performed by automatic or semi-automatic machines. Depending on the different variables, these machines age and thereby affecting both the quality of the manufacturing step and the resource requirements

2017 – 2018

Develop and validate predictive maintenance algorithms based on AI and ML. The vision is failure free production

2019 – 2022

2021 – 2024

e-FACTORY will enable companies to utilize digital tools as a means to obtain a number of different production values, e.g. increased capacity, improved quality, improved traceability, etc

2018 – 2020