DIGITAL work InStructions for cognitive work – DIGITALIS

Better work instructions for more efficient and inclusive work

2022 – 2025

Project time: 2020 – 2022

Budget: 12 150 000 kronor

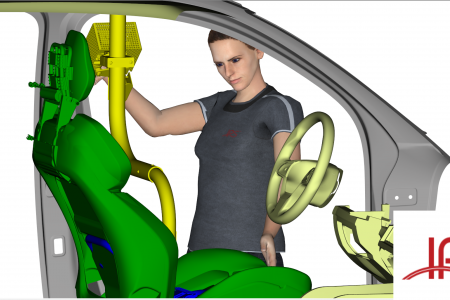

Analysis with Manikin for improved geometrical quality during manual assembly (AMIGO)

The goal of the project is to analytically determine the complexity level of manual assembly operations with the aid of a manikin to achieve better geometric quality. The project intends to take traditionally soft values and convert them into hard numbers and facts that can be proactively incorporated into new products and systems.

The news is to fusion two research tracks into one. In one track, the basis for the relationship between assembly ergonomics and geometric quality has been explored and an assessment criteria for assembly ergonomic complexity have been developed and implemented in a CAT tool. In the second track, a biomechanical model of a human has been developed to virtually model, simulate and optimize an operator’s movements during assembly.

The aim is to develop a comprehensive solution that enables you to simulate and proactively predict a system solution with regards to both the product quality and the fitter’s conditions and working environment. In addition to this, a completely new unique methodology will be developed to transfer deviations from the product to assembly simulation and simulate how these affect the operator’s work environment.

Better work instructions for more efficient and inclusive work

2022 – 2025

RECO will bring new knowledge and methods to improve quality by handling geometrical variation in composites.

2021 – 2024

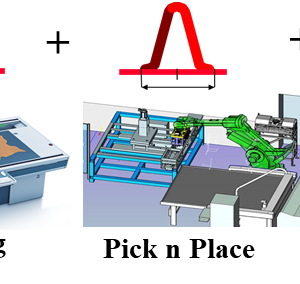

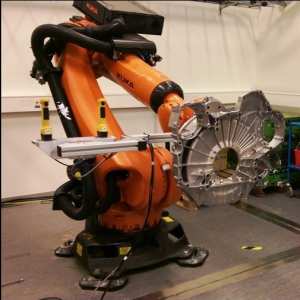

Development of a comprehensive model for safe installation of collaborative robots

2016 – 2018

Tidsättning av manuell montering är centralt för verkstadsindustrins konkurrenskraft.

2021 – 2024

The project's goal is to assist industry enabling sustainable work for operators during assembly of wire harnesses.

2022 – 2025

The project will develop a demonstrator of a digital human modelling tool considering human diversity, to be used for design, optimisation, visualisation, and verification of vehicle assembly workstations.

2019 – 2022