Project time: 2016 – 2018

Budget: 5 500 000 kr

Funding: SIP Produktion2030

Development of a comprehensive model for safe installation of collaborative robots

Smaller collaborative robots have been commercially installed the last years. However, commercial installations w ith robots large enough to lift and hold components that otherwise would require operators to use lifting tools are rare. Here, humans and robots actually hold components together. Today, there is no comprehensive work model to identify and manage all work place safety and ergonomics issues that emerge when collaborative robots are to be installed. Our idea is to develop a generic model for collaborative safety analysis and utilization of safety techniques based on the ISO/TS 15066 standard applicable for industry use. Such a model could increase the robot installation rate and tap the full productive potential for collaborative robot installations in Swedish industry. Our approach will be to identify the limitations of current safety assessment procedures in industry when analyzing potential collaborative robot applications, take advantage of state-of-the-art safety techniques for collaborative robotics, particularly collision avoidance strategies, and complement the current safety assessment procedures to incorporate collaborative robots. The updated procedures will facilitate higher MRL for collaborative robot installations, and are based on results from the ongoing FFI-project Team of Man and Machine (ToMM) where efficient management of safety issues have been identified as crucial for collaborative robot project success.

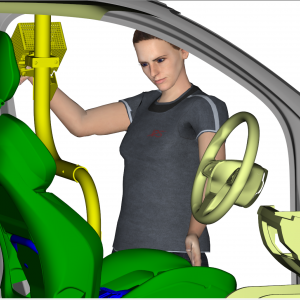

The project will develop a demonstrator of a digital human modelling tool considering human diversity, to be used for design, optimisation, visualisation, and verification of vehicle assembly workstations.

2019 – 2022

The project's goal is to assist industry enabling sustainable work for operators during assembly of wire harnesses.

2022 – 2025

Tidsättning av manuell montering är centralt för verkstadsindustrins konkurrenskraft.

2021 – 2024

Better work instructions for more efficient and inclusive work

2022 – 2025

Analysis with Manikin for improved geometrical quality during manual assembly (AMIGO)

2020 – 2022