Kristina Wärmefjord

Professor

Project time: 2021 – 2024

Budget: 9 500 000

Funding: SIP Produktion2030

RECO will bring new knowledge and methods to improve quality by handling geometrical variation in composites.

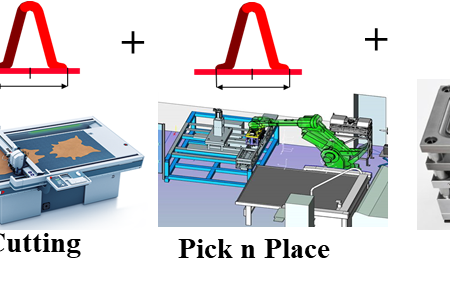

RECO contributes with new knowledge and methods for handling geometric variation in composite materials. Resilience is treated both in terms of resistance to sources of variation in manufacturing, and as resilience in the supply chain as more suppliers will meet the requirements due to better variation management. The project promotes the use of lightweight materials, improves geometric quality and shortens lead time. RECO involves project partners and other related stakeholders in workshops, interviews, case studies and through demonstrators. The project promotes the use of lightweight materials, improves the geometric quality and shortens lead time. Product quality is increased through smart assembly solutions and simulations, instead of stricter tolerances and higher requirements on the suppliers. To develop an adaptive assembly process and increase knowledge of part and assembly deviations based on simulation is increasing manufacturing flexibility and creates a more resilient manufacturing and supply chain to reduce costs, lead time and/or improved quality results.

RECO comprises five work packages. These cover project management including training initiatives and steering group meetings, development of simulation algorithms to predict part deviations and deviations on assembly level, integration of these in a geometry assurance process for composite materials and finally a demonstrator.

Vinnova dnr: 2021-03678

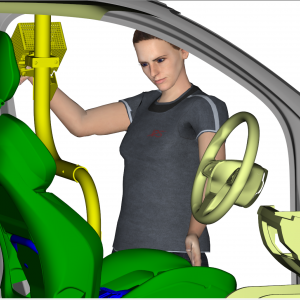

Analysis with Manikin for improved geometrical quality during manual assembly (AMIGO)

2020 – 2022

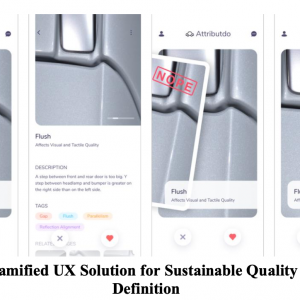

Two major disruptive trends – electrification and digitalization are changing customer preferences, leading to the probably most substantial transformation in the automotive industry we observed in decades. Finding a balance between customer’s requirements towards “zero-emission vehicle,” “connected car,” choice of materials, clarity of functions, and interface modes under the pressure of production time and cost are not easy. The AttributDo-project aims to help engineers create, define, verify and validate new and existing design features for new product development.

2021 – 2021

By estimating the material conditions and system errors, adaptive fixture and process can minimize variations.

2018 – 2019