Cecilia Goyenola

Ph.D. Materials Science

Project time: 2021 – 2024

Budget: 3 660 000 kr

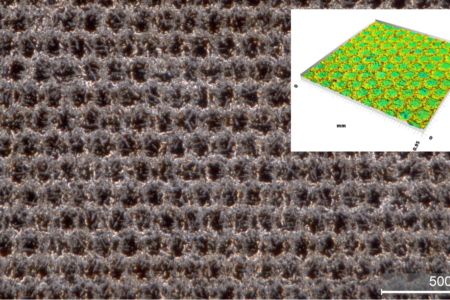

Demonstrating the effectivity of laser texturing before thermal spraying in an industrial environment

The project LaTex tackles the challenge area ”Resource-efficient production” by focusing on the surface preparation processes before thermal spraying. LaTex proposes the substitution of the traditional multi-step grit-blasting process by a one-step automated laser texturing. The overall goal of the project is to demonstrate the effectiveness and benefits of laser texturing before thermal spraying in industrial environments.

The expected effects are many-fold, some of which are:

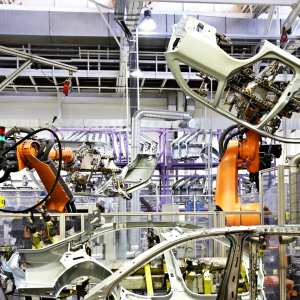

The paintshop is often a bottleneck in production and the processes are fine-tuned based on testing on numerous prototypes. To meet the future demands there is a great need to improve the product preparation process. The aim is to develop methods, techniques and software, and supporting measurement methodology, for simulation of paint curing in IR and convective ovens. The goal is to assist the industry to further develop and optimize their surface treatment to be more energy and cost efficient; to have a shorter lead time in product development; and to give a higher product quality.

2016 – 2019

Implementation of thin film pre-treatments to replace ZnPh for a more sustainable and cost-efficient production.

2019 – 2022

Digi-load focuses on to enhance the competitiveness in the Swedish surface treatment industry through automation and digitalization

2017 – 2020

Novel methods, techniques and software for simulation of electrodeposition and galvanization processes.

2020 – 2023