Project time: 2019 – 2022

Budget: 12 810 000 kronor

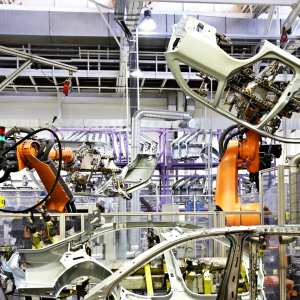

Implementation of thin film pre-treatments to replace ZnPh for a more sustainable and cost-efficient production.

The most important pre-treatment technology used by the automotive industry today is based on zinc phosphating (ZnPh). Previous studies have shown how thin film pre-treatment techniques are promising alternatives for both single- and multi-material applications to offer a more environmentally neutral and cost-efficient production through fewer process steps and reduced energy, water and chemical consumption. However, for implementation of thin film pre-treatment processes it is of outmost importance to develop methods and acquire more knowledge, and forming guidelines, for process verification and long-term stability. In this project a subcontractor to the automotive industry and one of the automotive companies will setup thin film lines parallel to the ordinary ZnPh-line. Other automotive companies within the project will have the possibility to evaluate the two different systems in parallel and to produce demonstrators. The pilot plants will also be one place to evaluate the process stability as well as in-line verification methods. The project is expected to deliver guidelines for process stability, process monitoring and handling of materials and baths. Suitable methods for in-/at-line analysis as well as more detailed analysis of the pre-treatments/coatings will be reviewed. Existing accelerated corrosion test methods will be adjusted/improved to fulfil the implementation prerequisite of verification of the corrosion resistance of components or standardized specimens pre-treated with thin film techniques. Finally, the knowledge will be summarised in a guideline for implementation and a life cycle assessment of the two lines will be performed

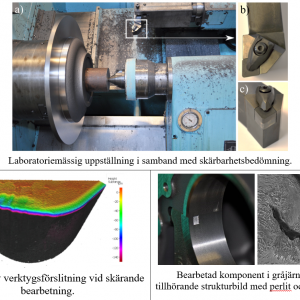

Reduced variation in machinability promote lower costs, predictable and a sustainable processing of grey cast iron components.

2020 – 2022

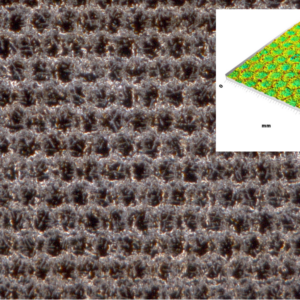

Demonstrating the effectivity of laser texturing before thermal spraying in an industrial environment

2021 – 2024

The paintshop is often a bottleneck in production and the processes are fine-tuned based on testing on numerous prototypes. To meet the future demands there is a great need to improve the product preparation process. The aim is to develop methods, techniques and software, and supporting measurement methodology, for simulation of paint curing in IR and convective ovens. The goal is to assist the industry to further develop and optimize their surface treatment to be more energy and cost efficient; to have a shorter lead time in product development; and to give a higher product quality.

2016 – 2019

Novel methods, techniques and software for simulation of electrodeposition and galvanization processes.

2020 – 2023

Digi-load focuses on to enhance the competitiveness in the Swedish surface treatment industry through automation and digitalization

2017 – 2020