LOVIS4C – Logistic Visibility for Circularity

LOVIS4C – explore supply chain visibility as enabler of circularity

2022 – 2023

Professor in Production logistics

E-mail: magwik@kth.se

Affiliation: Royal Institute of Technology

Academy: Production Academy

Design, modelling and performance prediction of production logistics.

Magnus Wiktorsson is a Professor within Production logistics at KTH, Royal Institute of Technology, in Södertälje, Sweden. He is also head of department for the department of Production Engineering (IPU) at KTH in Stockholm and Södertälje. His research interest concerns operations management and production logistics. Connected technologies and digital tools as enablers for analysis and development of sustainable production, are common themes in his research.

He has a background as senior lecturer, associate professor and professor at Mälardalen university during 2008 – 2017. After his PhD in 2000 he worked as a management consultant at IBM and smaller partner-based consulting companies, focusing on operations management. He also worked as a Program Manager at VINNOVA, the Swedish governmental agency for innovation systems, funding research projects within product realisation. He graduated from the Royal Institute of Technology in Stockholm with an MSc in Systems Engineering (1995) and a PhD in Manufacturing Engineering (2000).

With an academic background in applied mathematics and systems engineering, and an industrial background in operations management, Magnus analyse production logistic systems with respect to efficiency, sustainability and performance.

LOVIS4C – explore supply chain visibility as enabler of circularity

2022 – 2023

Tidsättning av manuell montering är centralt för verkstadsindustrins konkurrenskraft.

2021 – 2024

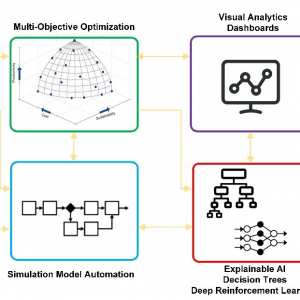

AI for supporting decision-making and learning, not replacing jobs in production

2021 – 2024

Demonstrate solutions for visibility in production logistics, for dynamic abilities and resource efficiency.

2019 – 2022

The project's aim was to study how to create driving force for improvement work and development of production systems with increased environmental focus

2011 – 2013

2010 – 2011

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

2017 – 2020

The project focuses on how to reduce waste/cost caused by environmental aspects and adding value to the production system by green strategies and actions

2009 – 2012

2014 – 2017

2013 – 2016

Innofacture är en Företagsforskarskola som bedrivs i samverkan mellan Mälardalens högskola och tio av landets största tillverkningsföretag. Projektet fokuserar både på innovation och produktion för att utveckla produktionsprocesser i företagen.

2012 – 2021

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

The purpose of the ProLoc project is to create a new type of decision model to assist in the production location decisions, being increasingly important in a world with high rates of change.

2010 – 2013

The overall aim is to strengthen the Swedish manufacturing companies competitiveness through increasing the production competence and develop their production capabilities

2010 – 2012

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017