Project time: 2021 – 2024

Budget: 12 132 349 kronor

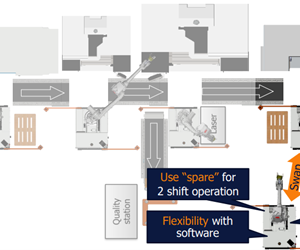

Robotic solutions with autonomous decision-making software supporting on-demand production using resource pools.

The mega trend of high mix and low volume production affects many industrial sectors. The ability to produce different products, on demand, in the same system, improves the utilization of resources, energy, space, etc., while allowing companiesto engage in more dynamic marketplaces. The food and beverages sector is characterized by seasonal variability and products have important variations in form factor. High volume production systems with fixed automation are deployed for catering for the throughput needs of certain products. However, the industry is seeing an important increase in custom orders. Due to variations in volume and nature of the custom orders it is not possible to incorporate them directly in the main lines. Simultaneously, conventional automation is not cost effective, leads to very low utilization of resources, inadequate use of space and lack of flexibility. The project will develop the technology for incorporating robots on demand, as a function of the customs orders. It develops in three important directions. A robotic solution that can operate without fences and can be very easily displaced within the same site or between sites, using forklifts. An intelligent optimization and execution middleware that ensures the robot and surrounding environment operate in a plug and produce way. The concept of dynamic resource pools that will enable companies to share physical resources within and between sites. The depalletization and repalletization processes investigated have the biggest economical and sustainability impacts and include the highest variation in product manipulation requirements. While addressing an immediate business need, they pave the way for generally reconsidering the design of automation systems.

2014 – 2016

Reduced lead times and improved performance for tooling through innovative manufacturing and assembly strategies as well as optimised design enabled by use of additive manufacturing (AM).

2016 – 2018

The main idea of the project is to investigate and demonstrate how the digitalized and proven systems and technologies of the Process Industry, like CPAS, can be used in DM to improve competitiveness and drive growth

2017 – 2019

2014 – 2017

The aim of the project is to demonstrate utilization of additive manufacturing for copper-based products and process solutions and faster adaption

2016 – 2018

2016 – 2018

2013 – 2016

This project aims to contribute to the development of future ERP-systems. The project will explore how to offer work, redefine work roles and challenge companies to make use of advanced systems support and the technology within and around these. Overall, the project aims to contribute to the development of both the next generation of ERP-systems and a complementary change in the way firms see upon work organization, so that technology can support and meet the needs of the humans within organisations rather than enforcing structures upon them.

2019 – 2019

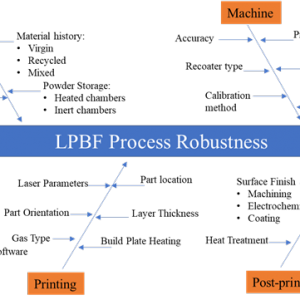

Assessing the Robustness of the Laser Powder Bed Fusion Process

2021 – 2024

The project aims to develop a new cyber-physical framework to realize extremely flexible production.

2021 – 2024