Ulf Bodin

Associate Professor

Project time: 2019 – 2019

Budget: 500 000 kronor

Funding: SIP Produktion2030

SeeCut focuses on cost-efficient production systems for secure collection, analysis, visualization, storage and sharing of production data. The project addresses the integration of new signals and sensors. For advanced products, like jet engine components, collecting data during manufacturing and usage is essential for quality assurance and remanufacturing. The project goals are to identify key technical requirements related to production data for use in digitalized value chains, define means to ease the run-time integration of new signals and data streams from manufacturing machinery and sensors, and define how to securely and cost-efficiently share data through the value chains in circular production.

2017 – 2018

2017 – 2018

Increased sustainability and cost effectiveness through improved strategic decision-making in production issues based on new metrics system for production and development.

2015 – 2017

Every manufacturing company measure and control production performance with a system of KPIs. The aim of the SMART-PM project is to investigate and demonstrate new ways of collecting data, transforming data to information and introducing new decision tools based on valid information and economic models of the production systems.

2018 – 2020

Development of a thermo-chemical test bed and implemenation of results for chosen processes and applications

2019 – 2022

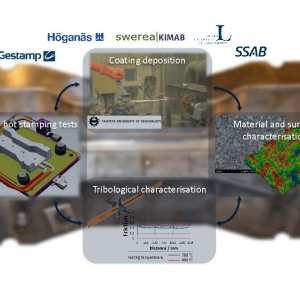

Tooling constitutes a significant part in the economical investment of the hot stamping process. Significant benefits in production economy and environmental benefits can be attained by improving the tribological performance in hot forming operations of automotive components. The main idea of this project is to create tailored tool surfaces on dies made from cheaper and easier to manufacture tool steel for the hot stamping of ultra-high strength steels.

2015 – 2018

2014 – 2017

2014 – 2017

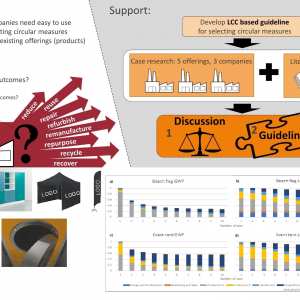

The project focuses on economic and environmental sustainability and increased industrial competitiveness.

2017 – 2018

2017 – 2019

2015 – 2016

2016 – 2019

2015 – 2016