Difficulties in joining are often a limiting factor for vehicle manufacturers during product weight reduction.

The aim of JODIMACO is to enable efficient and robust joining of aluminium to ultra-high strength steel in car bodies, which is a requirement for realising e.g. lighter electric vehicles with longer range and maintained collision safety.

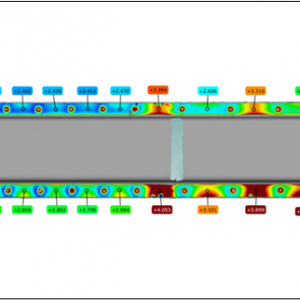

The goal is to achieve joining of multi-material combinations which cannot be welded or joined by traditional multi-material processes, e.g. SPR (self-piercing riveting) or FDS (flow drill screwing). A major limitation of SPR and FDS is the inability of the processes to penetrate ultra-high strength steel, over 600 MPa, during joining to aluminium details. Interesting material combinations within the automotive industry, which will be investigated, include cast and extruded aluminium to boron steel. The processes EJOWELD (from EJOT) and SPACPLUG (from RB&W) will be examined more thoroughly. Joinability, the effect of incorporation of adhesive and robustness will be key aspects for the project. The component approach of the project will facilitate in implementation and enable flexible production systems, with high quality assurance, cost effectiveness and manufacturing of products with high lifecycle effectiveness.

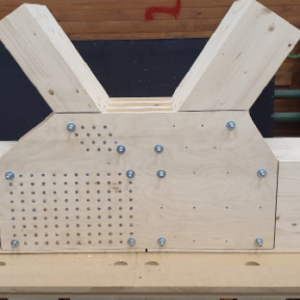

The consortia consist of companies and individuals with great knowledge throughout the production chain, and include material manufacturers, joining solution suppliers and Original Equipment Manufacturer. Relevant joining solutions will be implemented in a test environment (Testbed Joining), joining methodology and guidelines will provide a foundation to future internal technical standards. Component demonstrators joined according to the methodology generated will be part of the project deliverables.

Kunskapsförmedlingen

Kunskapsförmedlingen