Tord Cedell

Project time: 2017 – 2018

Budget: 500 000 kronor

Funding: SIP Produktion2030

Traditional soldering of heat exchanger plates is carried out batchwise by time-consuming heating in an oven with vacuum or protective gas atmosphere. The industry seeks a production flow, where each product is treated separately at different stations. By using ohmic heating directly on the heat exchanger package, short cycle times, low energy consumption, easy conversion, and high, measurable quality can be achieved.

The aim of the project has mainly been to be able to build up enough knowledge under

the preliminary study, to be able to create a technical assessment basis for assessment of whether it is possible to use ohmic heating for soldering heat exchanger packages.

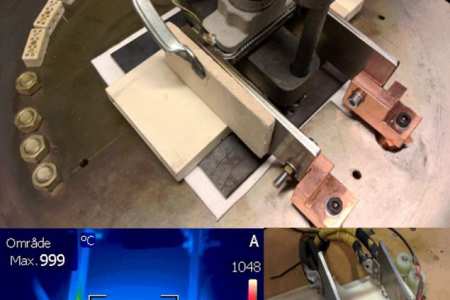

This was achieved by building a demonstrator that resistively can heat a heat exchanger package in such a way that the same melting process (of the solder) and the same quality output (bonding, tightness, repeatability, etc.) as in traditional batch heating in autoclave.

By moving the solder of heat exchanger plates from a large, slow batch oven to a small,

flexible fixture that is heated with direct current, will result in considerable energy savings as well as

cost savings. At the same time, single-piece production is possible in short heating cycles with one

simple and flexible equipment. The project has shown that it is possible to heat quickly and accurately with the proposed method, but also that there are several major technical challenges, including uniformity in the heating pattern.

The project has been implemented jointly by project partners in a number of smaller work packages.

Power electronics have been built on existing solutions, but have required modifications. Work on designing and building a test unit has been the dominant activity and the project was

completed with verifying tests on representative packages as well as demonstration of

the technique. Since the project has been carried out as a preliminary study for limited time, only lab scale verification in was conducted.