Flexible Additive Manufacturing of Micrometer/Millimeter Wave Components (FAMWAVE)

The goal is to demonstrate the additive manufacturing of micrometer/millimeter wave components.

2019 – 2022

Project time: 2021 – 2024

Budget: 9 891 189 kronor

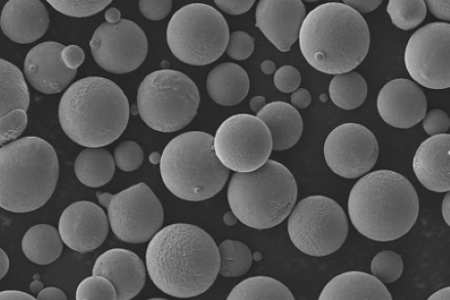

Powder metallurgy is an attractive, alternative method to manufacture large components for nuclear power plants.

Sweden has a strong base and knowledge on component manufacturing through powder metallurgy hot isostatic pressing (PM HIP) and can provide world class, sustainable products following the highest quality standards. The method is highly attractive for the manufacture of heavy components for nuclear power plants (NPPs), as alternative manufacturing methods are increasingly being sourced for to meet the requirements of the industry. This initiative handles further development of the PM HIP technology in purpose to improve the material properties and performance of the product above that possible to achieve by the traditional PM HIP. The new advancements rely on a use of a novel concept that can be integrated to existing technology. It is resource efficient, can be controlled by digital sensors and operates under conditions that are economically viable. The scope of this initiative is to verify that improved material properties can be attained for heavy PM HIP components. A controllable manufacturing system will be realized and utilized for a production of a massive component. The properties and structural integrity of the component will be compared to the codified requirements addressed for the final application. The excellence of this proposal is unique in global perspective and will improve the competitiveness of the Swedish PM HIP industry in range of applications. The end-users will be provided a path for sustainable manufacturing of both advanced light water reactor and small modular reactor components addressing short- and long-term needs for fabrication of complex components. The society will benefit from sustainable energy transition.