Johan Ölvander

PhD Mechanical Engineering

Project time: 2021 – 2023

Budget: 7 199 780 kronor

AutoPack skapar optimala elkablageinstallationer baserat på optimering och maskininlärning. AutoPack delivers optimal cabling installations based on optimization and machine learning

AutoPack 2.0 wants to increase the degree of digitization and automation in the product- and production development process and to ensure that production and assembly aspects are taken into consideration early in the development process. The application of the project is packing and assembly of high-voltage cables and cable harnesses, which is a time-consuming and resource-intensive activity throughout the automotive industry. With the electrification of the vehicle fleet, the experience built up around the installation of hoses and cables for internal combustion engines needs to be renewed based on the new conditions that electrification entails. In order to meet these new requirements and to take production and assembly aspects into account in the early stages of development, both new methods and tools need to be developed. The proposed project is a direct continuation of the AutoPack project, financed via FFI-Machine Learning.

To define hoses, pipes and cabling installations at Volvo, tens of thousands of engineering hours are spent at a cost of tens of million SEK per year. With the help of further developing the Autopack toolbox, it is estimated that AutoPack 2.0 will deliver a 50% reduction in the engineering hours spent on packaging, production planning and assembly, and the corresponding cost savings.

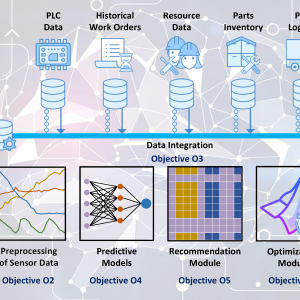

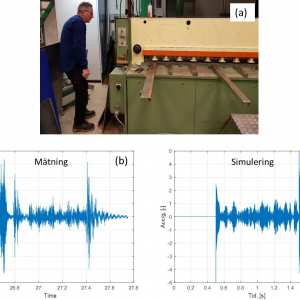

Develop and validate predictive maintenance algorithms based on AI and ML. The vision is failure free production

2019 – 2022

The goal of AutoFix is to increase automation of fixture design with integration of digital tools from different disciplines.

2020 – 2023

2021 – 2024

The aim is to develop new models for visualizing and predicting delivery schedule variations in supply chains.

2018 – 2021

Reduce the environmental impact of foundries by reducing the amount of sand waste using machine learning.

2023 – 2024

Industrial production systems typically include many process steps performed by automatic or semi-automatic machines. Depending on the different variables, these machines age and thereby affecting both the quality of the manufacturing step and the resource requirements

2017 – 2018

Prediktivt underhåll med internet-of-things och digitala tvillingar

2021 – 2021