Project time: 2018 – 2021

Budget: 9 185 000 kronor

The aim is to develop new models for visualizing and predicting delivery schedule variations in supply chains.

The project intends to contribute to the automotive industry competitiveness and work by developing new solutions for improved delivery schedule quality and value adding information sharing in automotive supply chains. The project will generate a wide description of information sharing and usage in supply chains. It will also generate machine learning-based models for measurement, visualization and prediction of delivery schedule quality. The models will be tested and assessed in field pilots.

The project is organized in six work packages. The first is a survey study of information usage in automotive supply chains. The second conducts data analytics of a large amount of delivery schedule data in order to identify common variations and patterns. The third conducts case studies to explain causes and consequences. The fourth develops new machine learning-based solutions/models for visualization and prediction. The fifth studies implementation and the sixth dissemination

Recent research from Chalmers have shown that by slightly tuning robot motions, the energy use can be reduced by 10 –30%, with preserved cycle time.

2017 – 2020

Increased digitalization brings new possibilities for Swedish manufacturing companies. This project focuses on what data are needed to feed assembly variation simulation and how this data can be captured and stored efficiently and effectively. The project contributes to increased geometrical quality. The technical value chain from part inspection, to extraction of relevant data, storage of data, usage of data in variation simulation (as a digital twin) and to visualization of simulation results as decision support will be covered. This has the potential to replace prototypes/test series and saves cost, time and reduces the environmental impact.

2019 – 2019

2021 – 2024

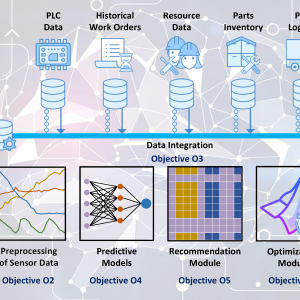

Develop and validate predictive maintenance algorithms based on AI and ML. The vision is failure free production

2019 – 2022

Prediktivt underhåll med internet-of-things och digitala tvillingar

2021 – 2021

Reduce the environmental impact of foundries by reducing the amount of sand waste using machine learning.

2023 – 2024

e-FACTORY will enable companies to utilize digital tools as a means to obtain a number of different production values, e.g. increased capacity, improved quality, improved traceability, etc

2018 – 2020

The goal is to mirror the production and make custom information available for industry personnel.

2018 – 2019

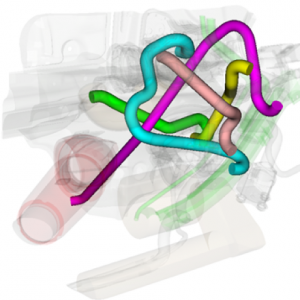

AutoPack skapar optimala elkablageinstallationer baserat på optimering och maskininlärning. AutoPack delivers optimal cabling installations based on optimization and machine learning

2021 – 2023

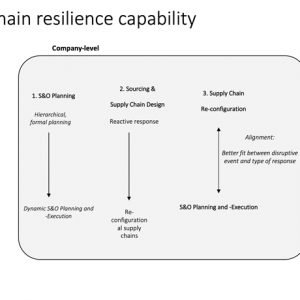

Building resilience by aligning supply chain reconfiguration with new ways of dynamic planning

2021 – 2024

The goal of AutoFix is to increase automation of fixture design with integration of digital tools from different disciplines.

2020 – 2023