Project time: 2021 – 2024

Budget: 4 625 000 kronor

Turn2Flex aims to increase the production flexibility for the manufacture of large sized bearings.

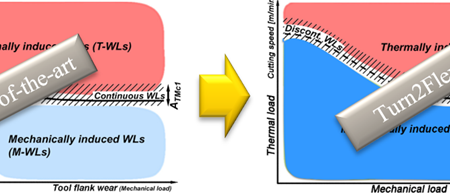

The current manufacturing of large size bearings is done in the following process steps: forming, soft machining, heat treatment, grinding, hard turning (HaT), polishing, etc., which helps to shape the bearings into the required dimensions and tolerances. Each and single process step has their limitations, which limits mass customization as well as it increases the manufacturing lead time and the production cost. Turn2Flex aims to increasing the production flexibility by reducing the number of process steps and increase the properties of the as-produced components via a novel hard turning strategy. This strategy will generate a unique high-strength metallic surface, called Mechanical White Layers (M-WLs), which will improve the surface mechanical properties and hence the life of the bearings at service. Turn2Flex aims to qualify the HaT process so it could potentially be used as a finishing process, that significantly will increase production flexibility through enabling rough and finish machining in one clamping setup, reduce the manufacturing lead-time, the energy consumption and enable mass customization. The project connects to the 7th, 8th, 9th and the 12th sustainability development goals in Agenda 2030 goals in securing a sustainable industry with innovation capacity as it aims at providing solutions to advanced Flexible Production through innovative and resource efficient technologies like HaT. This will be demonstrated through the selected target application, which if proven successful, could constitute a significant breakthrough for future product realization and becoming a game changer within the manufacturing industry.