The cluster for geometry and quality is one of eight clusters within the Swedish Production Cluster. The cluster focuses on research and development in geometry and quality assurance in product design and manufacturing.

Effective geometry and quality assurance in product design and manufacturing are a prerequisite for achieving customer satisfaction; this also reduces the risks of late adjustment costs, delays, and warranty costs. In a total perspective, it also involves sustainability, Geometry, and Quality Assurance aims to produce less scrap and provide more accuracy in product and processes. A critical enabler is the standards for specification and verification and that they are understood and interpreted equally by all involved.

Product and process specifications and requirement management

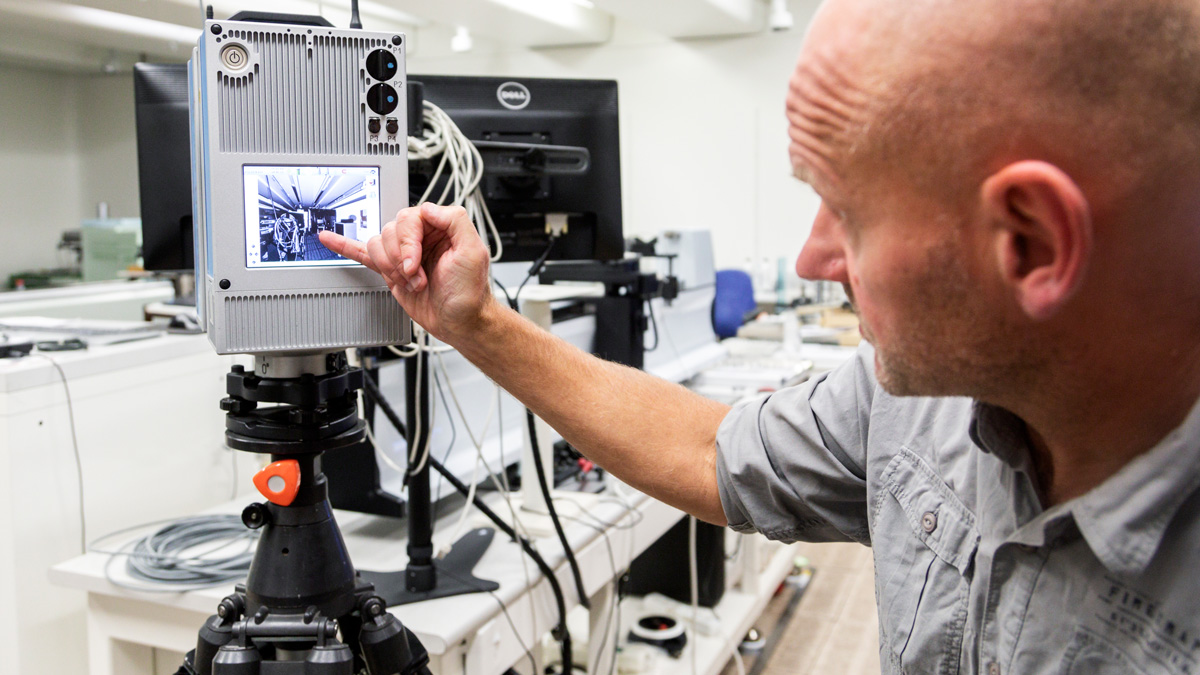

Tools and methods for measurement and quality planning

Verification technologies and quality control

The aim is to develop economically and environmentally sustainable manufacturing systems capable of effectively providing the market with the innovative products of the future. Through the cluster’s working methods, we strengthen Sweden’s continued success as a sustainable industrial nation. You can win this by participating:

Cluster members: Sandvik Coromant, NEVS, RISE Research Institutes of Sweden, SAAB Group, Scania, Volvo Group, Volvo Cars, Husqvarna Group, Hexagon, Väderstad, Valmet, Tetrafix, Lidhs, Lars Hammare Utbildnings AB, Cascade, KTH.

The cluster welcomes more companies! Please, contact us for more information!

Coordinator: Helena Björk, RISE