Ocean-LSAM

To lay the foundation for tomorrow’s network of circular economy microfactories producing products designed by Swedish industry and produced from local recycled plastics.

2022 – 2023

Project time: 2021 – 2024

Budget: 5 900 000 kr

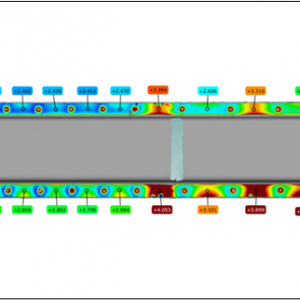

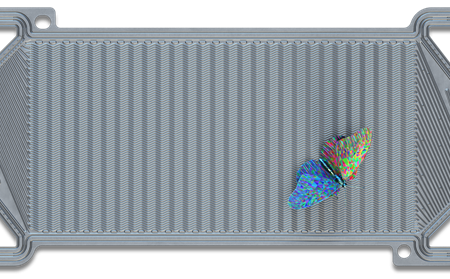

New designs for fuel cell plates can be introduced faster and cheaper using efficient modeling technology

The project focuses on using numerical modelling to connect the final geometry of metallic bipolar plates (BP) for fuel cells with high tolerance requirements, manufactured with a high-speed forming process where the complex shape and dynamic behaviour of the production tools must be included in a combined product and production development.

To date, BPs have mostly been made of plastic containing graphite. A metallic bipolar plate can be 30% smaller and 50% lighter and is made of recyclable material. In addition to weight and space advantage, costs can be reduced with metallic bipolar plates in the case of large quantities in series production.

By developing digital methods for implementing product designs through realisation of tools for production the design process will be faster resulting in cheaper and more robust solutions thus providing ability to adapt to changing conditions and quickly produce newly developed patterns for BP.

The originality in this proposal lies in the combined area of challenges addressed i.e. tribology, numerical modelling, high speed forming process and demanding requirements in integrated product and production development.

Shorter time from design to production contributes to resilience as disturbances from e.g. tool wear and havoc can be remedied faster. Improved modelling of tooling and high-speed forming process accounting for surface conditions enable faster and cheaper realisation of new BP designs. The market for BP is global and a lead for Swedish industry makes it possible to take large market shares for the benefit of Swedish industry in the entire supply chain to BP. This enables transition to fossil free energy technology and will create a substantial amount of new jobs.

The project’s objective is to combine product and production development for fuel cell plates to manage rapid adaptation of new designs to give Swedish competitiveness and reduced environmental impact.

To lay the foundation for tomorrow’s network of circular economy microfactories producing products designed by Swedish industry and produced from local recycled plastics.

2022 – 2023

The project will create a digital tool for solving the largest issue in multi-material design: the Δα-issue.

2020 – 2023